A cylindrical cell pilot plant refers to a specialized facility or setup designed for the pilot-scale production of cylindrical lithium-ion battery cells. These pilot plants serve as crucial intermediaries between laboratory-scale research and full-scale commercial manufacturing, allowing for the testing, optimization, and scale-up of battery cell production processes. Here's an overview of a cylindrical cell pilot plant:

Purpose and Importance:

Cylindrical lithium-ion battery cells, characterized by their cylindrical shape, are widely used in various applications such as consumer electronics, electric vehicles, energy storage systems, and portable devices. Establishing a Cylindrical Cell Lab Plant is essential for several reasons:

Process Optimization: The pilot plant enables researchers and engineers to optimize key parameters of the battery cell manufacturing process, including electrode formulation, coating techniques, cell assembly methods, and quality control procedures.

Scale-up Studies: By operating at a pilot scale, the plant facilitates the evaluation of production scalability, assessing the feasibility of transferring laboratory-developed processes to larger-scale commercial production facilities.

Quality Assurance: Pilot-scale production allows for the validation of product quality and performance metrics under conditions that closely resemble full-scale manufacturing, ensuring consistency and reliability in the final battery cell products.

Cost Analysis: Pilot plants provide valuable insights into the cost structure of battery cell production, including material costs, labor costs, energy consumption, and equipment depreciation, aiding in the assessment of economic viability and competitiveness.

Components and Configuration:

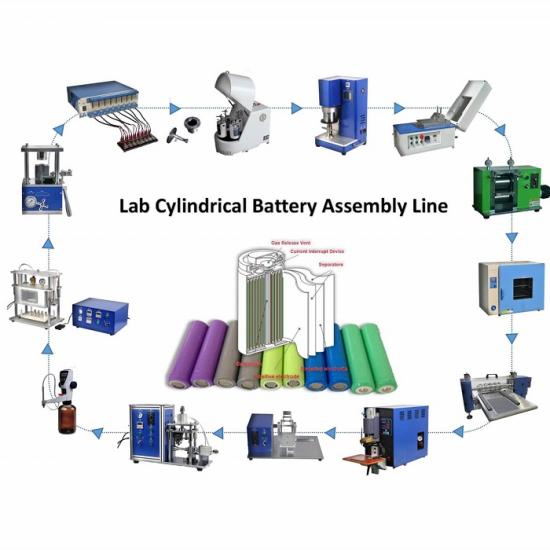

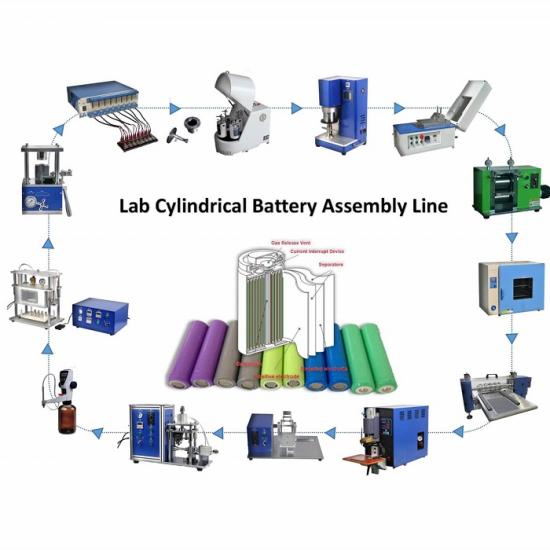

A typical Cylindrical cell making Plant consists of several key components and units:

Electrode Preparation Unit: This unit includes equipment for preparing electrode materials, such as mixing, coating, calendaring, and drying equipment. It ensures the uniform and precise deposition of electrode materials onto current collectors.

Cell Assembly Line: The assembly line comprises machinery for the stacking, winding, and sealing of electrode layers, separators, and current collectors to form complete battery cells. Automated equipment may be used to improve efficiency and consistency.

Formation and Testing Station: This station is dedicated to the initial charging and discharging (formation) of battery cells to activate them and establish their electrochemical performance characteristics. Testing equipment is used to assess cell performance, capacity, cycle life, and safety.

Quality Control and Analysis Lab: Equipped with instrumentation for analyzing electrode and electrolyte materials, monitoring process parameters, and conducting quality control tests on finished battery cells. This lab ensures compliance with specifications and standards.

Safety Systems: Pilot plants incorporate safety features such as ventilation systems, fire suppression systems, emergency shutdown procedures, and personnel protective equipment to mitigate risks associated with handling hazardous materials and operating high-energy processes.

Applications and Advantages:

Cylindrical cell pilot plants support research and development efforts aimed at improving battery performance, enhancing energy density, extending cycle life, and reducing costs.

They enable the rapid prototyping of new battery chemistries, materials, and manufacturing processes, accelerating innovation cycles in the battery industry.

Pilot-scale production allows for the production of small batches of battery cells for testing in prototype devices, experimental vehicles, and pilot-scale energy storage systems.

By providing a platform for collaboration between researchers, manufacturers, and end-users, pilot plants facilitate knowledge exchange and technology transfer, fostering industry-wide advancements.

Future Trends:

As demand for high-performance and cost-effective lithium-ion batteries continues to grow, cylindrical cell pilot plants are expected to evolve in several ways:

Advanced Automation: Integration of robotics, artificial intelligence, and machine learning algorithms to automate and optimize production processes, reducing labor costs and increasing throughput.

Flexible Manufacturing: Modular and reconfigurable production lines that can accommodate multiple battery chemistries, cell formats, and production scales to meet diverse market demands.

Sustainable Practices: Adoption of environmentally friendly manufacturing practices, such as solvent-free electrode coating methods, recycling of materials, and energy-efficient processes, to minimize environmental impact and enhance sustainability.

New Materials and Technologies: Exploration of novel electrode materials, electrolytes, additives, and manufacturing techniques to push the boundaries of battery performance, safety, and reliability.

In conclusion, cylindrical cell pilot plants play a pivotal role in the development and scale-up of lithium-ion battery technology, enabling researchers and manufacturers to innovate, optimize, and commercialize advanced battery cells for diverse applications in energy storage and transportation. As the battery industry continues to evolve, pilot plants will remain essential platforms for driving progress and meeting the evolving needs of society.

ru

ru en

en fr

fr de

de es

es pt

pt ko

ko tr

tr pl

pl th

th

Поддержка сети IPv6

Поддержка сети IPv6